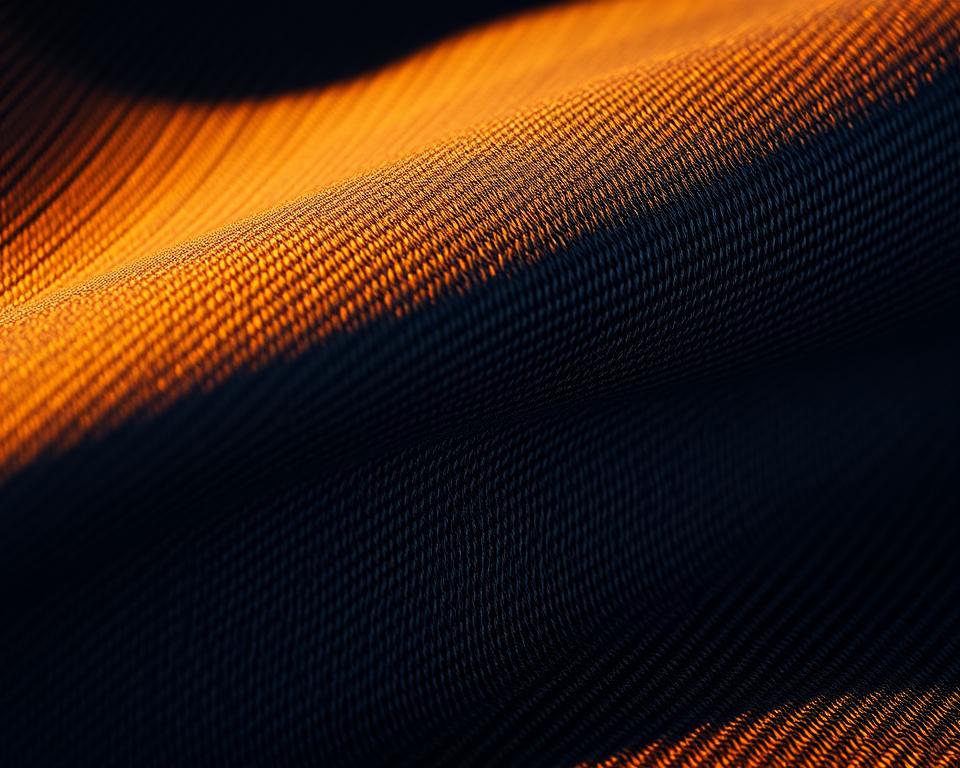

The Ultimate Guide for High-Quality denim Selvedge Material

Ever questioned why some trousers seem as though they are made to last eternity? The secret lies in the elements and skill. Consider the increasing popularity of premium selvedge. This isn’t just any material—it exemplifies quality and heritage.

Nowadays, more people are choosing these everlasting textiles for their durability and iconic ewingfly denim appeal. Be it that you are a DIY sewist or a denim aficionado, there’s an exceptional aspect about employing high-quality natural fiber and yarn. It goes beyond merely making trousers; it’s about producing a narrative.

Here at Core Fabrics, we’ve curated a selection of 14.25oz certified organic cotton and flexible options. These materials are perfect for a spectrum ranging from raw jeans to couture jacket designs. Ready to explore the realm of exceptional fabrics? Let’s jump right in.

Defining Denim Selvedge Fabric?

What is it that makes some trousers set themselves apart with their distinctive, naturally edged borders? The answer lies in the selvedge denim, a premium fabric celebrated for its robustness and retro appeal. Differing from regular textiles, this type of fabric is crafted with time-honored methods that have endured through ages.

What Selvedge Denim Means

Selvedge denim is produced using retro shuttle looms, which yield narrow widths of about 30-35 inches. These looms weave the material in a manner that ensures self-finished borders, often marked by a characteristic red line. This process ensures the material is densely interlaced and exceptionally sturdy.

Contemporary looms, on the other hand, produce expansive material but do not offer the equivalent of artistry. The imperfections in selvedge, like misaligned seams or uneven textures, are celebrated as elements of its beauty. This ideology, termed “the beauty of imperfection”, honors the appeal of natural flaws.

Production of Selvedge Denim

The manufacturing of selvedge denim entails a detailed process. Shuttle looms cross the horizontal threads alternately, resulting in a dense and resilient material. This method contrasts with modern looms, which prioritize quick production and efficiency over craftsmanship.

Labels such as Karson Denim preserve time-honored Japanese methods from the nineteen-nineties. They purposefully add imperfections to preserve the authenticity of the fabric. Each piece is graded on a 4-point system, ensuring it fulfills the highest standards of quality.

| Feature | Selvedge Denim | Modern Denim |

|---|---|---|

| Width | 30-35 inches | 60+ inches |

| Weaving Process | Shuttle Loom | Modern Loom |

| Finish | Uneven, Imperfect | Uniform |

| Strength | Superior | Moderate |

“The allure of selvedge lies in its imperfections—each flaw tells a story craftsmanship and tradition.”

The History of Selvedge Denim

Evolving from simple roots to international fame, the tale of these materials is rich and inspiring. Originally developed as hardwearing clothing in the 17th-century France evolved into a mark of everlasting fashion and artistry.

Beginnings in Craftsmanship

The roots of this fabric reaches back to Nîmes, France, where it was known as “serge de Nîmes.” Originally designed for laborers, it was constructed with sturdy cotton and stitching. Its resilience made it a favorite among workers during the era of the Gold Rush.

By the 20th century, it had evolved into a essential element for trousers. The shuttering of the Cone Mills White Oak facility became a pivotal moment. This change opened the door for Japanese artisans to restore traditional weaving techniques.

Evolution in Modern Denim Production

Following WWII, Japan adopted retro American culture. Skilled workers restored old looms to produce true reproductions. This dedication to craftsmanship ensured the continuance of selvedge as a unique product.

In modern times, advancements from Italy and Turkey have introduced sustainable mixtures and elastic variants. These advancements have widened the allure of this timeless textile. Within Core Fabrics, we source globally, from Montréal to Asia, to deliver to you the top-notch excellence.

“The legacy of selvedge is a testament to the lasting worth of excellence and heritage.”

The Benefits of Selvedge Denim?

Why does selvedge denim shine in the universe of premium fabrics? Its unique qualities and incomparable robustness make it a favorite among lovers and designers alike. Whether you’re crafting jeans or a structured jacket, this textile provides a mix of classic methods and updated style.

Characteristic Features of Selvedge

Selvedge denim is known for its dense construction, which improves ripping resistance and color fading characteristics. Differing from regular textiles, selvedge denim material is produced using classic shuttle looms, creating a more compact and exceptionally sturdy fabric. In doing so, it secures that all products boast a distinct surface and individuality.

Here’s what makes it special:

- Coarse, stiff raw denim juxtaposes against pre-washed comfort stretches.

- The sanforization process ensures predictable sizing, while untreated fabrics provide a unique shrinkage journey.

- Weight options range from 9.5oz Eco Finish to 14.25oz Organic, meeting diverse applications.

Durability and Longevity

One of the key attributes of selvedge denim is its enduring nature. The tighter weave not only increases durability but also allows for distinctive color fades over time. This makes it a valuable investment for those looking for enduring style.

Key points to consider:

- 12-14oz weights are ideal for structured jackets and jeans that soften with age.

- For classic jean longevity, the 14.25oz True Indigo is a top recommendation.

- Sustainable variants such as recycled cotton combined with indigo blends enhance eco-friendliness.

At Core Fabrics, our collection includes a variety of options to suit your needs. Whether untreated or sanforized, every item is made to provide outstanding quality and performance.

Selvedge vs. Wide Denim: A Comparison

In the creation of robust and fashionable apparel, the decision of fabric plays a crucial role. Among the prevalent selections are selvedge and wide denim, both offering different features. Knowing how they differ assists in selecting the ideal material for your creation.

Distinct Weaving Methods

Selvedge denim is produced using traditional shuttle looms, producing limited spans of 30-35 inches. This herringbone denim material technique creates tightly woven edges, often accented with a signature red line. In contrast, wide denim is produced using modern projectile looms, resulting in widths of 60 inches or more.

Traditional shuttle looms operate at approximately 3 meters per minute, while contemporary projectile looms achieve up to 30m per minute. The variance in production speed affects both the expense and the finish of the final product.

Pros and Cons of Each Type

Selvedge denim is known for its premium quality and durability. Its limited breadth suits it well for projects where defined edges and detail work are sought. However, it can be more expensive, averaging $23 per meter.

Wide denim is economical, priced around $8 per half-meter. Its broader span reduces waste, making it suitable for big-scale works like upholstery. However, it lacks the unique edge finish of selvedge.

| Characteristic | Selvedge Denim | Wide Denim |

|---|---|---|

| Span | 30-35 inches | 60+ inches |

| Method | Shuttle Loom | Contemporary Projectile Loom |

| Production Speed | 3m per minute | 30m/min |

| Cost | $23/meter | $8/half-meter |

When precise, structured edges are required—as in Grainline Thayer jackets—selvedge wins out. Conversely, wide denim is ideal for extensive projects due to its efficiency. Weigh your requirements carefully to decide.

Maximizing Your Selvedge Denim

Working with premium materials can elevate your sewing projects to the next level. Whether you’re crafting jeans, blazers, or dresses, knowing how to measure, sew, and care for the material secures expert outcomes. Let’s explore how to make the most of this classic fabric.

Yardage Needed for Jeans and Jackets

Determining the proper yardage is key to a successful project. Approximately 3-3.3 yards is necessary for men’s jeans, considering defects and shrinkage. Trucker jackets typically require 3.3 yards, while skirts can be made with just 2 yards.

Innovative layout techniques can mitigate fabric flaws. Embrace the natural defects by weaving them into your creative design.

| Item | Required Yardage |

|---|---|

| Men’s Jeans | 3 to 3.3 yards |

| Work Jacket | 3.3 yards |

| Skirt | 2 yards |

Tips for Sewing and Care

Employing proper equipment and methods leads to an impeccable finish. Opt for #70–110 needles and presser foot attachments made for robust textiles. Gütermann rPET thread works well for contrasting stitches.

Here are some additional tips:

- Employ a tailor’s clapper to achieve crisp creases without gloss.

- Our denim kits from Core Fabrics comprise topstitch thread, rivets, and 9mm jeans buttons to ensure a refined result.

- Structured edges, essential for jackets, are best achieved with selvedge.

Correct care ensures your garments last longer. Use minimal washing and opt for air drying to preserve fabric quality. Adhering to these practices will sustain your creations for years.

To Summarize

Working with high-end textiles is not solely about longevity; it’s about infusing character. Selvedge denim epitomizes this philosophy, merging handcrafted appeal with long-lasting quality. From jeans to tailored jackets, every stitch of this material conveys a narrative.

With Core Fabrics, unleashing your creative potential is effortless. Our swatch service lets you touch and test the fabric before deciding. Additionally, benefit from complimentary shipping on orders exceeding $150 USD throughout North America.

Eco-friendly mixtures and classic washes are paving the way for the next generation of cotton fabrics. Such innovations provide novel methods for infusing eco-consciousness and fashion into your closet.

Eager to explore top-tier textiles? Begin your journey now and appreciate the merit of intentional crafting. Your next project could be a timeless piece that lasts for years to come.